The Helicoid™ Advantage

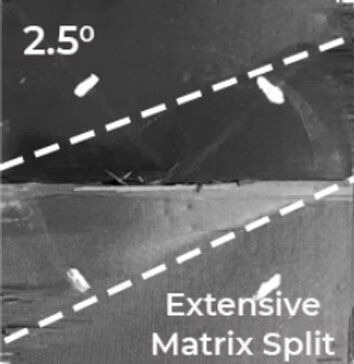

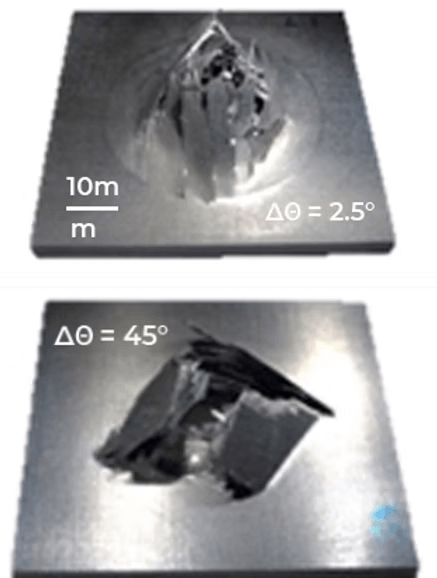

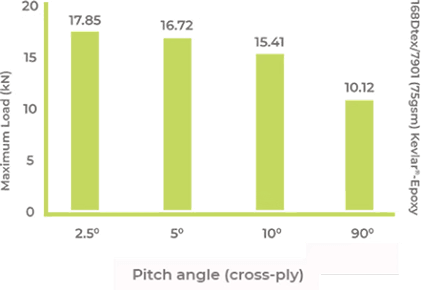

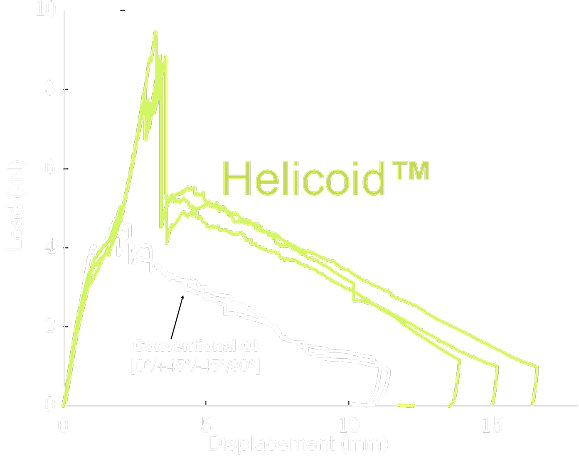

Notched bending tests performed on soft-polymer based helicoidal-inspired laminates show that decreasing the pitch angle leads to:

- a decreasing initiation value of toughness

- a more stable, highly dissipative failure process characterized by a larger post-initiation load-bearing capability and delayed catastrophic failure

- Higher structural integrity

- NO brittle catastrophic failure

- High energy absorption

- High residual strength in extreme load case scenarios

Performance Comparison

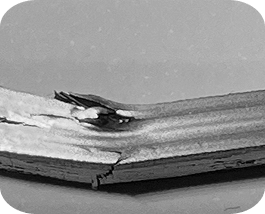

Sample did not break during our tests "ductile" fracture

vs

Fully broken in half during our tests

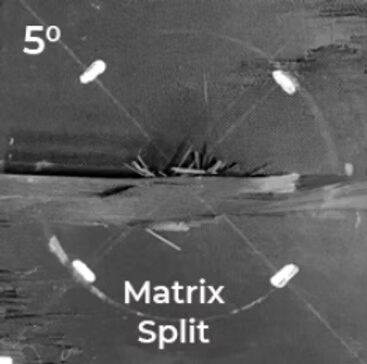

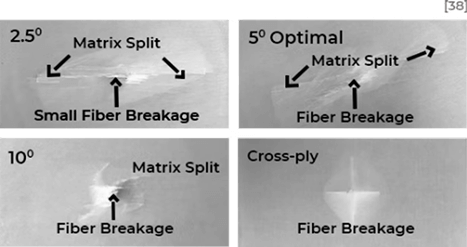

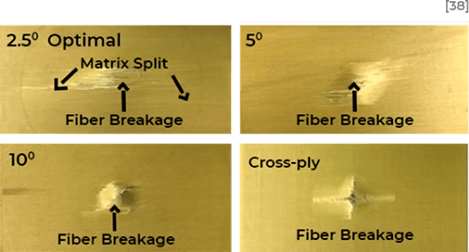

Tailored helicoidal Carbon Fiber Reinforced Polymer (CFRP) laminates are capable of enhancing the high-velocity impact resistance over similar conventional cross-ply laminates which results in a +23% increase in the required perforation energy. The balance between formation of matrix splits, helicoidal delaminations and fiber failure is key for the enhancement in high-velocity impact performance.

Performance Insights

Performance Comparison

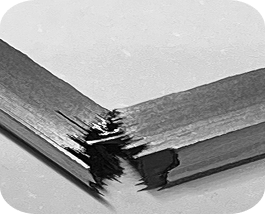

No Puncture - No fiber failure

vs

Puncture and fiber splintering

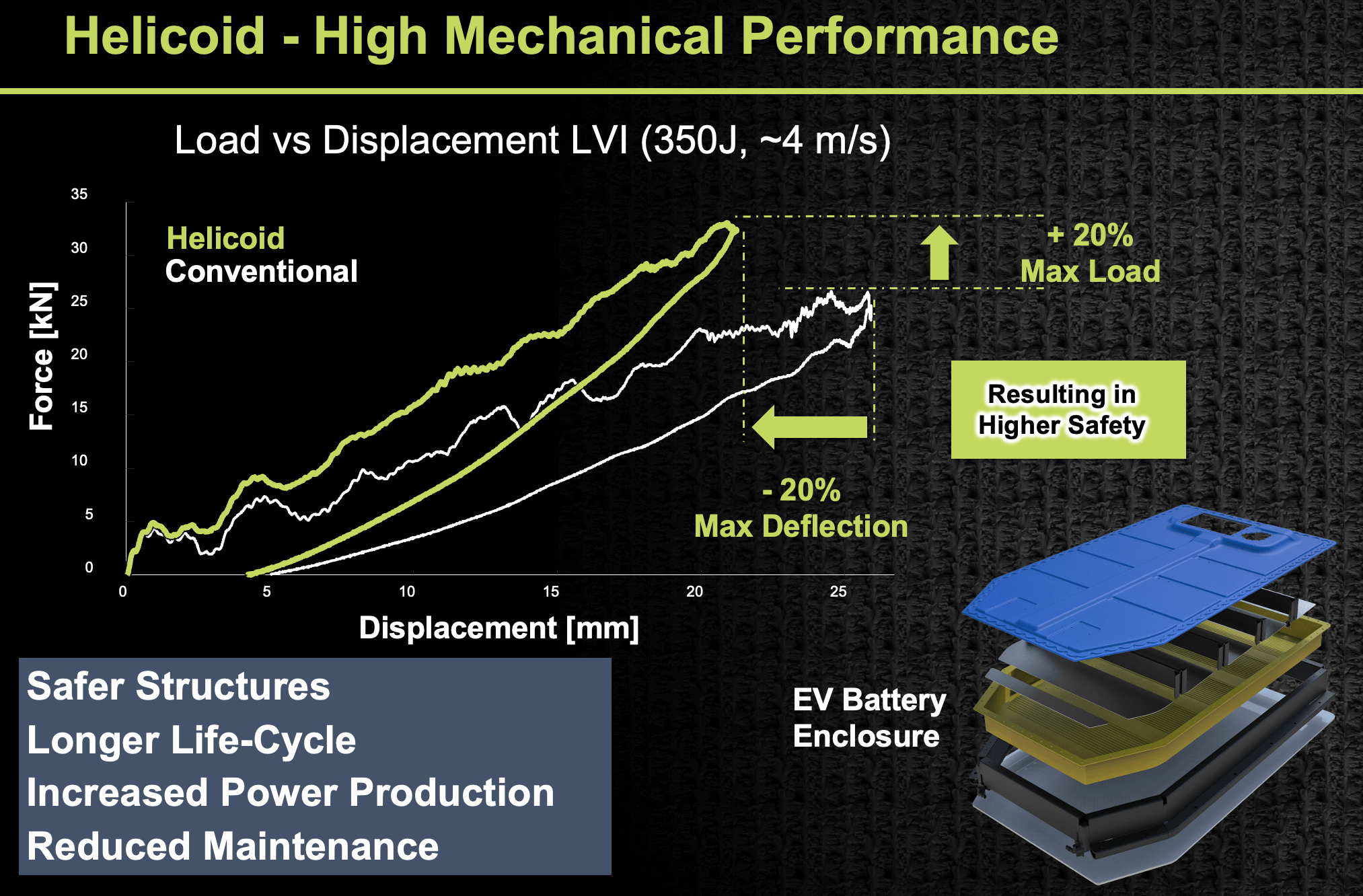

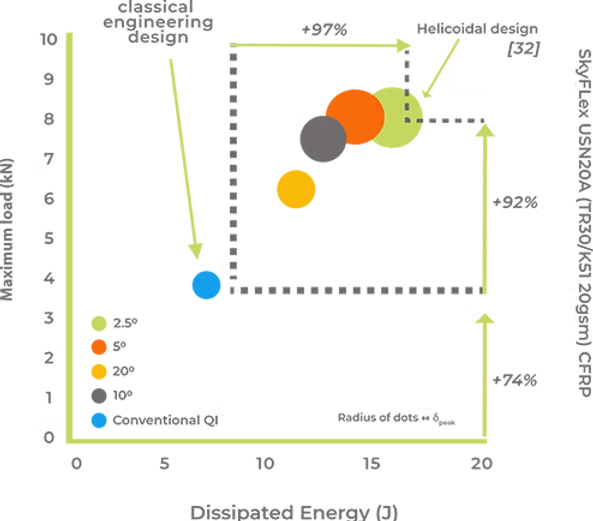

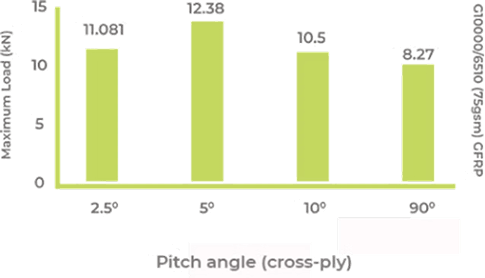

Reducing the pitch angle with Carbon Fibre Reinforced Polymer (CFRP) helicoidal structures leads to a simultaneous increase in (i) maximum load-bearing capacity (92%), (ii) delay in catastrophic failure (74%) and (iii) energy dissipation (97%).

The capability of helicoidal structures of dissipating energy through the activation of several sub-critical mechanisms such as helicoidal distribution of delaminations and twisting matrix cracks, allows to overcome the inherent low performance to out-of-plane loading of conventionally brittle CFRP (with standard lamination sequences).

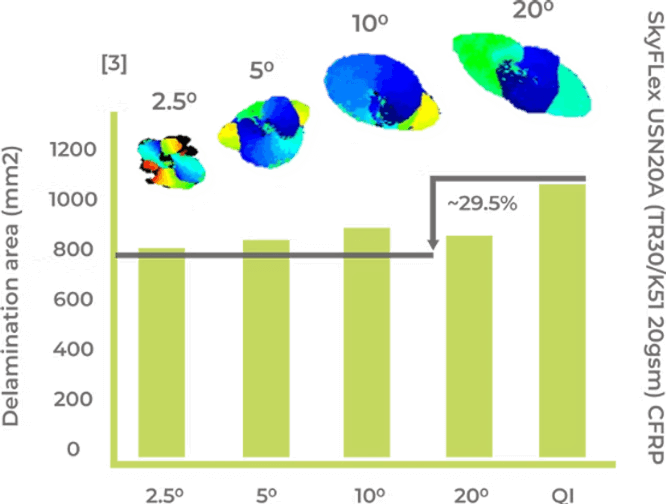

Growing sub-critical helicoidal damage, as opposed to localised large delaminations and fibre failure, is beneficial because it leads to improved damage resistance and mechanical performance to through-the-thickness loads.

This sub-critical damage can be promoted by tailoring the pitch angle down to an optimal value mainly depending on the specific ply thickness, resin-matrix interface and raw material mechanical properties.

Performance Insights

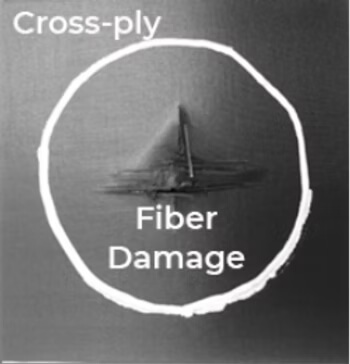

Performance Comparison

High structural integrity, NO perforation achieved, High residual strength

vs

Poor structural integrity, Fully perforated

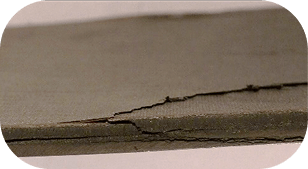

Helicoid laminates are capable of diffusing damage at sub-critical levels through the formation of matrix cracks, helicoidal delaminations and stable fibre failure.

Delaminations tend to be distributed helicoidally through-the-thickness of the laminate rather than being localised at a few ply interfaces.

The design of helicoidal laminates to resist impacts driven by the correct combination of pitch angle and number of plies for a given fiber/resin type, and ply thickness.

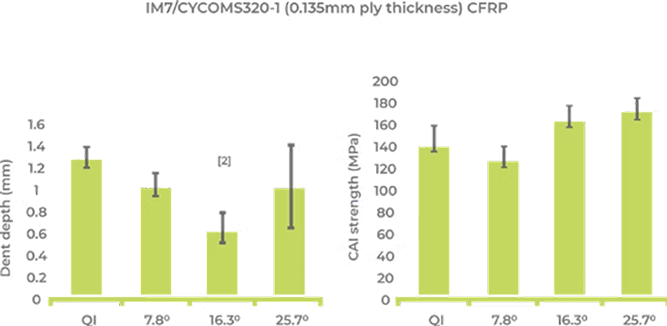

The outstanding capability of helicoidal FRP's to withstand localized delamination damage and delay fiber failure through sub-critical damage diffusion leads to Compression After Impact (CAI) strength similar to the one of conventional Quasi-Isotropic (QI) laminates. This is achieved with only 2.6% of the fibre oriented along the loading direction during compression against the much higher proportion of 0°-plies (26%) of the conventional QI laminates.

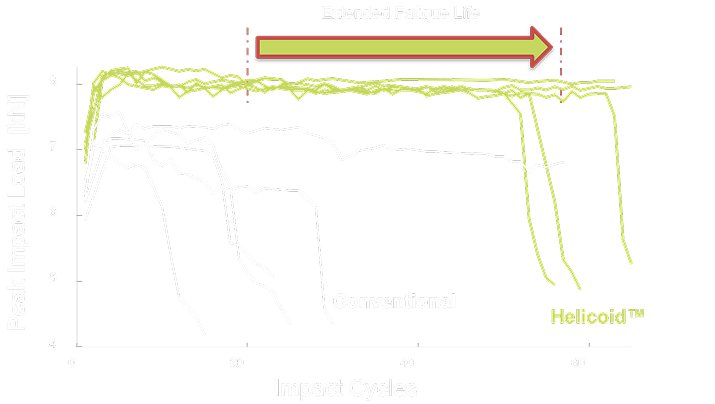

- 42% Higher Stiffness Retention

- 15% Higher Load Retention

- >90% Durability Improvement

Performance Insights

Performance Comparison

after 65 impacts

vs

after 25 impacts